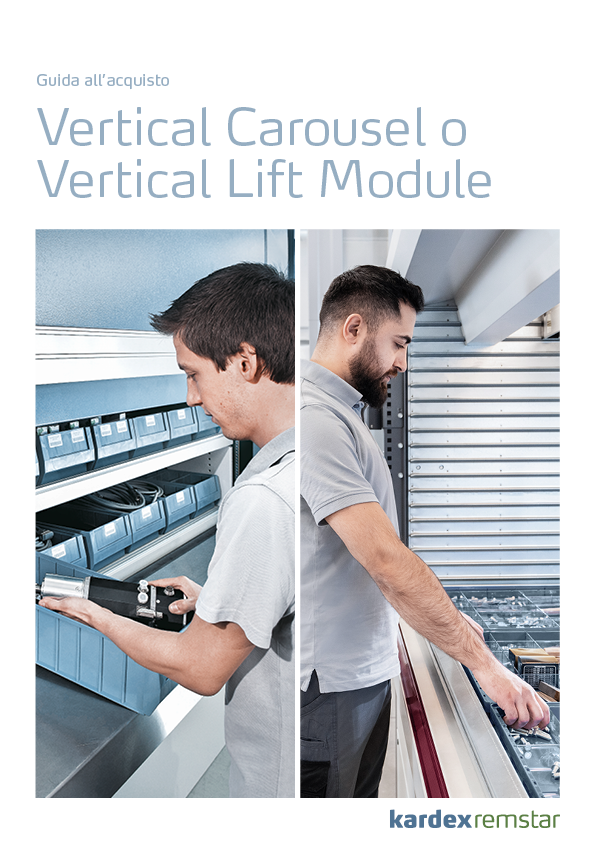

Vertical Lift Module (VLM) Sistema di stoccaggio automatico verticale a piani traslati progettato per aumentare la capacità di stoccaggio in un ingombro compatto.

Scopri oraSoluzioni AutoStore™ completamente integrate Porta l'evasione degli ordini a un livello superiore.

Scopri di piùOttimizzare lo spazio del magazzino Implementa l'automazione per aumentare la capacità di stoccaggio e ridurre al minimo l'ingombro.

SCOPRI ORAAumentare le prestazioni con l'automazione Scopri come ottimizzare le operazioni di magazzino

SCOPRI ORARivoluzionare il processo di prelievo Migliorare la velocità e la precisione di prelievo.

LEGGI QUISoluzioni per settore industriale

Come stocchi le tue referenze?

Sistema di stoccaggio automatico a cassette

Ottimizza i tuoi processi intralogistici con la nuova soluzione di stoccaggio automatico a cassette. Questo preciso sistema di stoccaggio e picking migliorerà nettamente i processi di evasione degli ordini permettendo allo stesso tempo di risparmiare spazio.

.jpeg)